Short course

Basics of Pneumatic Conveying

Nov. 12-13 | 8 a.m. to 5 p.m.

Course Description

Whether you're new to the field or looking to deepen your knowledge, this course equips you with the basic skills and insights needed to optimize your processes and enhance operational efficiency.

What is Covered?

- How does pneumatic conveying work?

- When is it appropriate, and when would a different type of conveying be better?

- What are all the components and how do they work?

- What is the difference between a pressure system and vacuum system, and what are the advantages and disadvantages of each?

- Dilute phase, dense phase, medium phase, vacuum sequencing – which type is the right one for various applications?

Instructors

Todd Smith

%5B55%5D.jpg?width=200&height=200&name=Todd%20Smith%20c%20(2)%5B55%5D.jpg) Todd helps lead K-State's Advanced Manufacturing and Bulk Solids Technology Center and serves as a board member for several industry organizations. Previously, Todd spent 38 years in the industry, first at four different DuPont plants, then as engineering manager at MAC Equipment (now Schenck Process), and then general manager of Coperion K-Tron Salina and vice president of the company’s Global Systems Group.

Todd helps lead K-State's Advanced Manufacturing and Bulk Solids Technology Center and serves as a board member for several industry organizations. Previously, Todd spent 38 years in the industry, first at four different DuPont plants, then as engineering manager at MAC Equipment (now Schenck Process), and then general manager of Coperion K-Tron Salina and vice president of the company’s Global Systems Group.

Jonathan McPherson

Jonathan McPherson is the director of K-State's Advanced Manufacturing and Bulk Solids Technology Center. Jonathan comes from industry having spent 11 years designing and commissioning material handling projects as a project engineer and developing business relationships in the markets of performance materials, battery and general industry as an account executive. His project backgrounds include plastics, PVC, paint, lead-acid battery, food and confectionary.

Jonathan McPherson is the director of K-State's Advanced Manufacturing and Bulk Solids Technology Center. Jonathan comes from industry having spent 11 years designing and commissioning material handling projects as a project engineer and developing business relationships in the markets of performance materials, battery and general industry as an account executive. His project backgrounds include plastics, PVC, paint, lead-acid battery, food and confectionary.

Learning objectives

At the conclusion of this course, students will understand the various types of pneumatic conveying, and know when and why to use each type. They will know why each component is important and how it works. They will know what it takes to design, operate, maintain, and troubleshoot a safe pneumatic conveying system for a variety of materials.

Who is it intended for?

Engineers, technicians, maintenance and operations personnel who work with bulk solid materials or the transportation.

Participants are encouraged to bring their specific questions and issues for discussion.

Format

This is an in-person course held at K-State Olathe, which is located at 22201 W. Innovation Drive, Olathe, KS 66061.

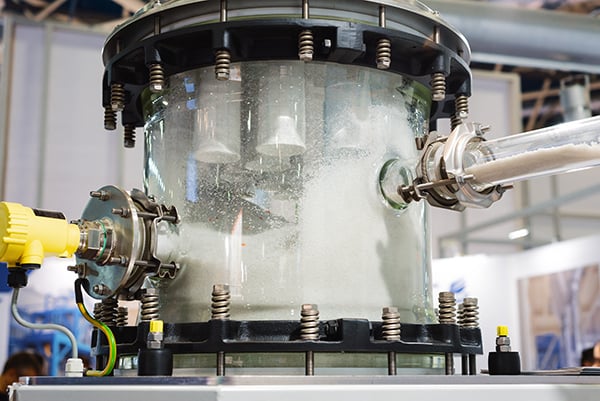

In addition, hands-on demonstrations of conveying and all componentry will occur at one of our company partners, located 15 minutes from KSU-Olathe.

Registration

Registration for this event has reached capacity. If you have any questions or would like to join a waitlist, please reach out to Jaclyn Wolf at jaclyn14@ksu.edu.