Learn. Lead. Succeed.

Strategies in Manufacturing: Optimizing Your Leadership

Who is this series for?

This series is for frontline managers, supervisors and team leads in manufacturing environments who want to enhance their leadership and management skills in order to optimize their team's performance and interactions.

What will you learn?

• How to leverage personal leadership skills to optimize team productivity

• Strategies and tools that foster collaboration, improve communication and increase engagement

• Tips and tools for tough conversations

• A clear, consistent approach to problem-solving

• How to give and receive effective feedback to achieve results and improve productive capabilities

• How to use data to drive performance and set individual and team goals

What is the time commitment?

You'll meet on the four Fridays in February (Feb. 6, 13, 20 and 27). Each of these in-person sessions is a full day, running from 9 a.m. to 4 p.m. In case of inclement weather, Friday, March 6, will serve as a make-up date for any canceled session.

There also will be a 75-minute virtual follow-up session during the week of March 23. Each instructor will choose a day and time to offer a virtual group facilitation and coaching session. Participants will select a session and sign up with the corresponding instructor.

In total, this program requires a 29-hour and 15-minute time commitment.

Develop the leaders who drive your production floor

Frontline leaders play a critical role in productivity, safety, workforce retention and operational excellence. This program equips emerging and current supervisors with practical leadership tools — built for the realities of modern manufacturing — so they can lead high-performing teams and support your strategic goals.

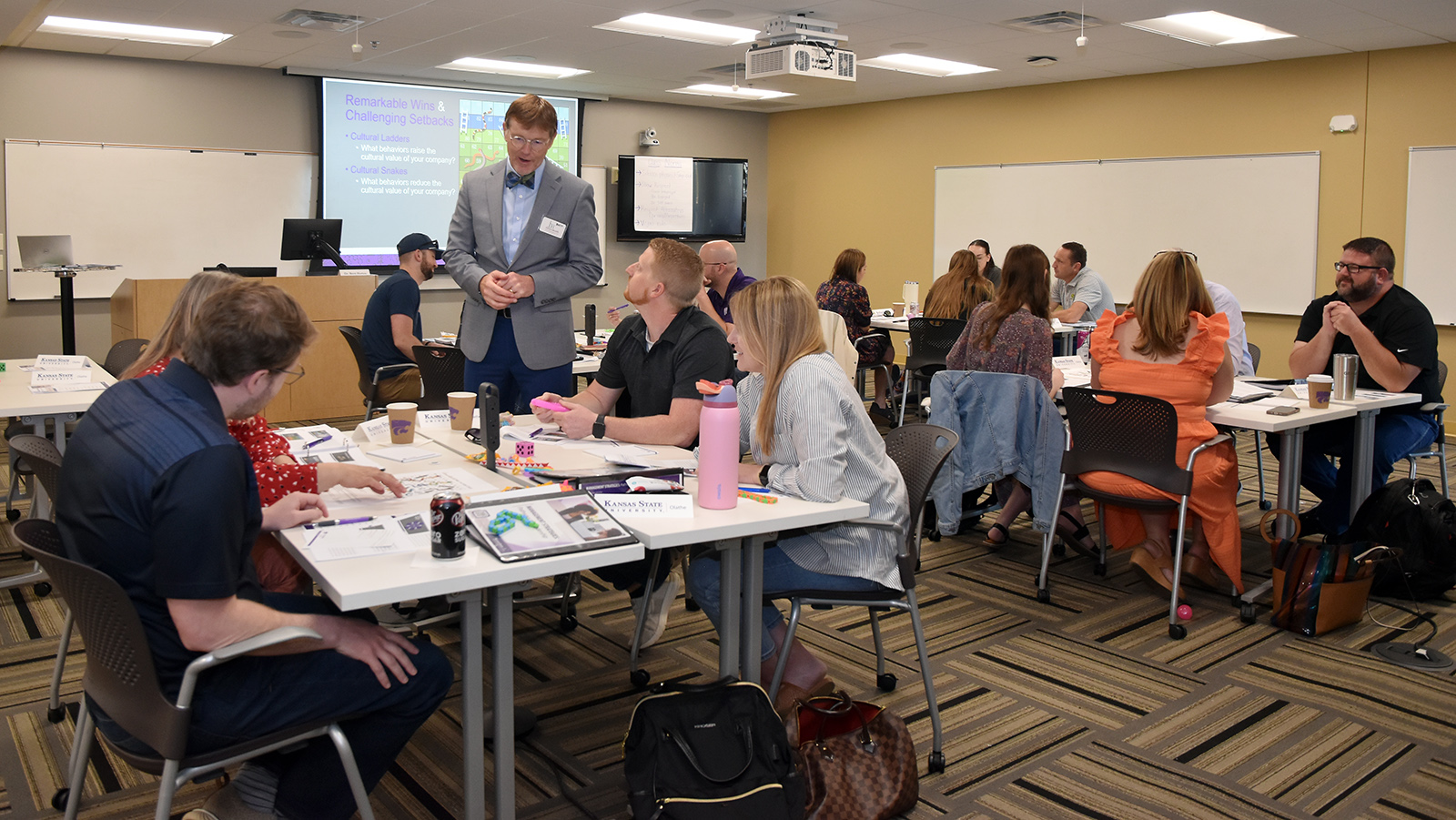

This series is specifically designed for those frontline managers, supervisors and team leads working in KC's advanced manufacturing industries. Throughout four days, they'll learn new skills, practical strategies and how to solve real-world challenges that routinely impact their workplace.

Schedule and Format

This series consists of four day-long sessions held in-person every Friday in February 2026. All in-person session are at the K-State Olathe campus, located at 22201 W. Innovation Drive, Olathe, KS 66061. A virtual group coaching session will follow-up the series the week of March 23. Lunch is provided at each in-person session.| Feb. 6 Session 1 |

Feb. 13 Session 2 |

Feb. 20 Session 3 |

Feb. 27 Session 4 |

Week of March 23 Virtual Session |

KC OPS Membership

Attendees also will receive and 3 month preview membership to KC OPS, a leadership development program for production managers working in manufacturing and fabrication firms in the Greater Kansas City area. Learn more about KC OPS.

Attendees also will receive and 3 month preview membership to KC OPS, a leadership development program for production managers working in manufacturing and fabrication firms in the Greater Kansas City area. Learn more about KC OPS.

Learn. Lead. Succeed.

Registration for Feb. 2026 has closed.

Don't miss the next opportunity. Sign up below to receive updates and be the first to know about new offerings.

Topics Covered and Additional Benefits

Throughout the series, participants will learn new skills, practical strategies and how to solve real-world challenges that routinely impact their workplace. This series is offered as a cohort model, meaning the same attendees will interact and engage with each other throughout the series. By doing this, they'll build a network of peers who work in the same industry and who they can turn to for shared problem-solving, advice and collaboration.

Session 1 is about optimizing team productivity.

Feb. 6 | Led by Judy Favor

Session 2 covers the multigenerational and globalized workplace and tough conversations.

Feb. 13 | Led by Meaghan Bircher and Judy Favor

Session 3 covers problem-solving and effective feedback.

Feb. 20 | Led by Brett Horton and Margie Banach

Session 4 is about data and goal setting, and includes break out groups.

Yellow Belt Lean Six Sigma Course

June 25-26, 2026

This optional, two-day introductory noncredit course is the foundation program of Lean Six Sigma and its methodologies. The main goal of the Yellow Belt course is to provide an introduction to Lean Six Sigma and how it can be used by individuals and teams to improve customer satisfaction, reduce errors, increase efficiencies and work more effectively with teams to solve problems.

Questions

Contact Dianna Bartel at kcprofdev@ksu.edu with any questions about the series.